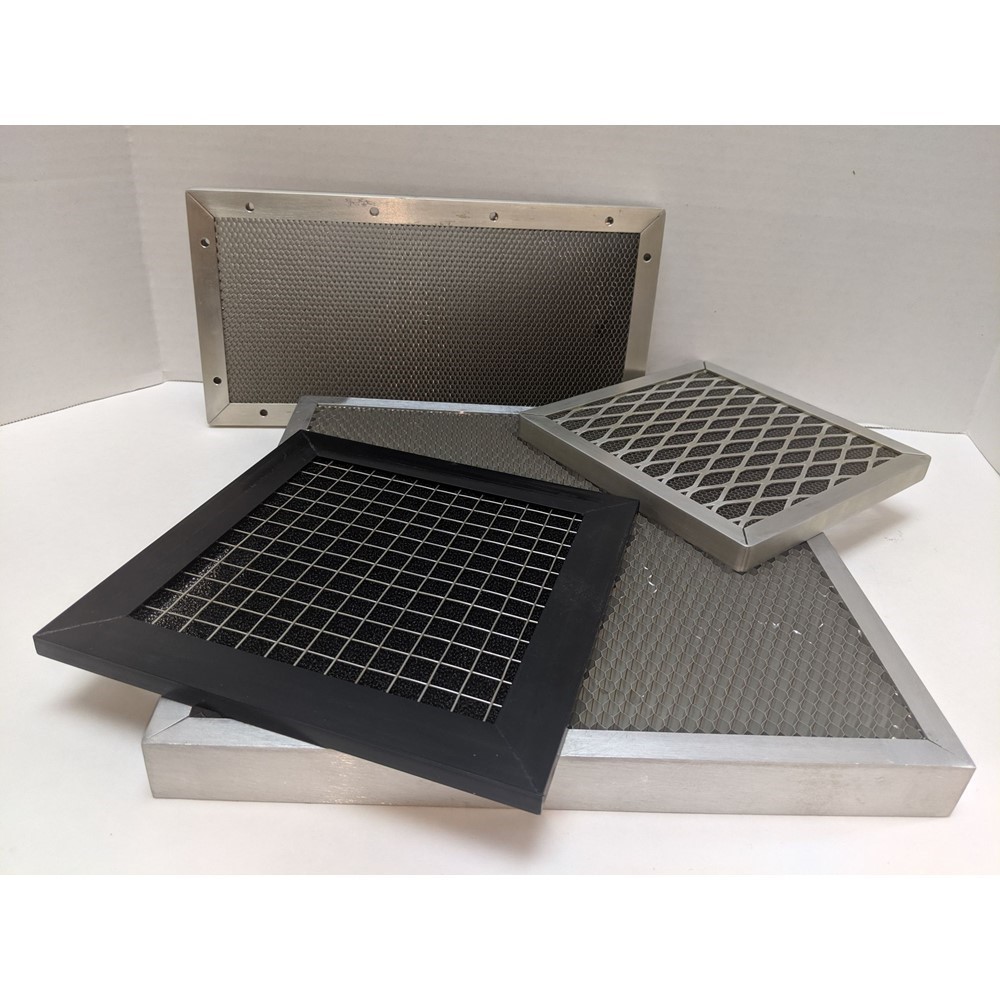

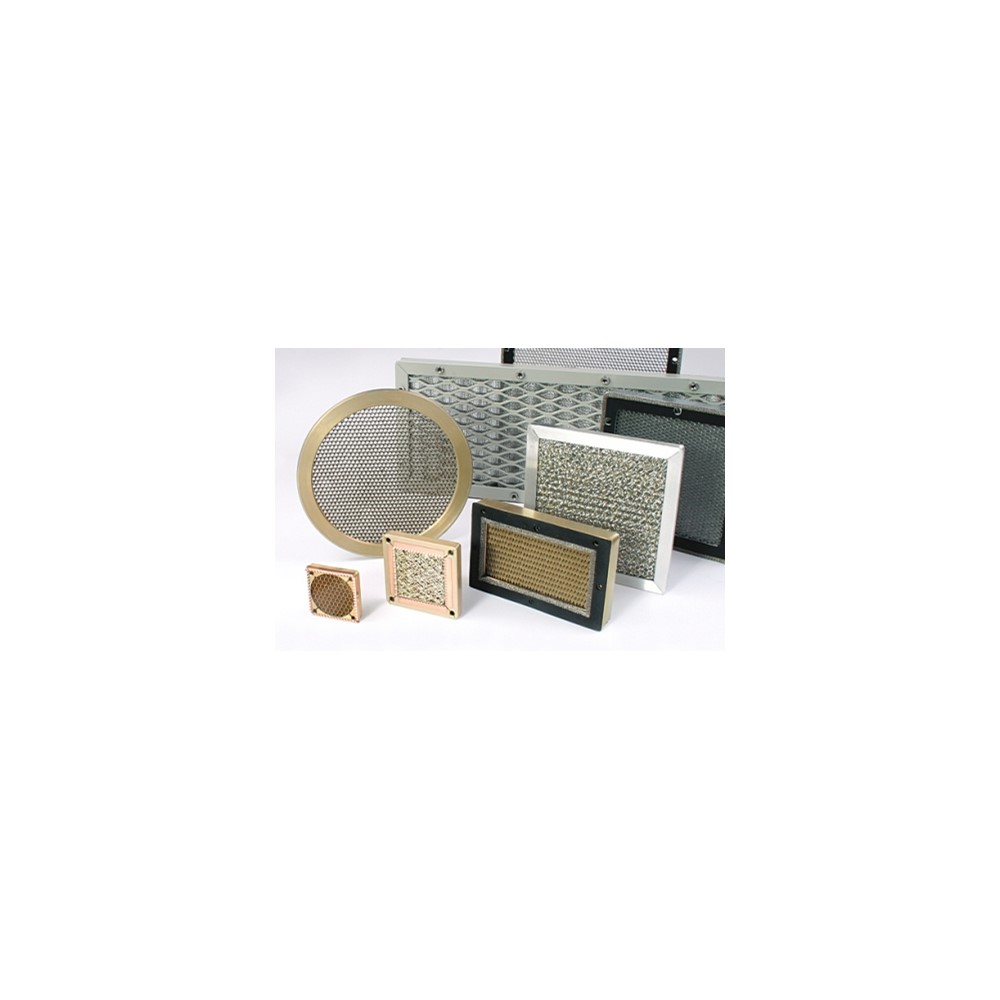

Vents panels are made using 5052 grade aluminium foil which is a lightweight material which offers superior strength and corrosion resistance compared to other commercial grade aluminium foils. It meets all the requirements of MIL-C- 7438. This material is used to manufacture aircraft floors, wing edges, missile wings, helicopter rotor blades and other aerospace related parts, so quality and repeatability is assured. All Vents are supplied with a conductive gasket to provide the best electrical contact between the frame and mating metal surface.

Using SemPas finishing, it fully meets the RoHS directive and replaces the previously used Alocrom 1200. This in-house process applies a permanganate passivation which is a chromate free, inorganic and nontoxic coating. The process produces a dense, uniform coating consisting of aluminium and reduced manganese oxides giving a golden yellow colour to the surface. The surface finish is conductive with a low contact resistance equalling Alocrom 1200. It also meets all requirements of MIL-C-5541E for corrosion and electrical conductivity.