What is Form-in-Place Gasket (FIPG)?

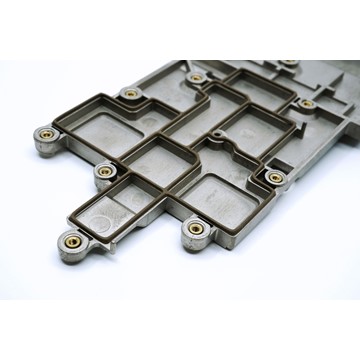

Form-in-Place gaskets (FIPG) are designed to replace conventional gaskets & O-rings, and involve dispensing conductive or non-conductive elastomers directly onto metal or plastic substrates. Conductive materials are typically applied to electronic components or devices for EMI & RFI shielding, and non-conductive materials are used for environmental sealing or bonding.

Formed-in-place gaskets (FIPG) have been in use for a few decades in the automotive industry. Many applications are in the power train system – engine & driveline. This would include engine block to oil pan, engine cover to engine block, intake manifolds, thermostat housings, pump covers, power steering housings, etc. Additional applications are in components, particularly electrical components and lamps, such as headlamps, side markers, etc.

Advantages of Form-in-Place Gasket (FIPG)

Less Waste & Greater Cost Savings

EMI & RF shielding materials can be expensive. There is significantly less material waste with FIP, and our dispensed form-in-place gaskets offer significant material cost savings when compared to conductive die cut gaskets.

Shorter Lead Times

The automated FIP process speeds up production by eliminating the need for manual assembly of die cut or moulded gaskets.

Material Combinations

With dozens of material to choose from, Form in Place gaskets are ideal solutions for countless applications. Conductive silicone compound is available with a number of fillers, such as Ag/Al, Ag/Cu, Ag/glass, Ni/C, Ni/Al and Carbon black.

Excellent Adhesion

FIP materials adhere to a range of substrates, including conductive & painted plastics, metals & metal alloys, and metallized surfaces.

Greater Precision & Tighter Tolerances

Form-in-place gaskets can be dispensed on intricate work pieces, including those with changes in elevation. Our CNC robots were developed to dispense precise form-in-place gasket beads on even the most complex work pieces. Gaskets requiring thin profiles, our robots easily dispense intricate shapes and/ or changes in the Z-axis or elevation.

Applications of Form-in-Place Gasket (FIPG)

Dispensed gaskets are perfect for use in many telecom, aerospace, industrial, high technology, medical equipment & military applications.

Some specific applications include the following:

- Sealing joints

- Insulating electrical components

- Joining dissimilar materials, like metal & plastic

- Shielding mobile phone base stations & telecom equipment from EMI & RF interference

- Producing a large series of aluminium castings where both a low risk of galvanic corrosion & excellent shielding are required